The Ultimate Guide to Value Chain Management: How AI Reduces Inventory Costs by 30% in 2025

- VCM Management

- Dec 5, 2025

- 5 min read

Let's be honest: you're probably tired of watching cash disappear into inventory black holes. You know the frustration: too much stock gathering dust in warehouses while your bestsellers mysteriously run out just when demand peaks. Your finance team keeps asking why inventory carrying costs eat up 25-30% of your product value, and you're stuck making gut-feel decisions with spreadsheets that were outdated the moment you opened them.

We get it. After working with hundreds of companies struggling with these exact challenges, we've seen how traditional inventory management turns smart business leaders into reluctant fortune tellers, desperately trying to predict what customers will want three months from now.

But here's what's changed in 2025: AI has finally moved from buzzword to bottom-line impact. Companies implementing AI inventory solutions are now achieving 30% reductions in inventory costs: not through magic, but through systematic elimination of the guesswork that's been bleeding your cash flow dry.

Why Traditional Inventory Management Is Failing You

How many times have you asked yourself: "Why do we always have too much of what nobody wants and not enough of what everyone needs?"

This isn't a failure of planning: it's a limitation of human-scale analysis. Traditional inventory management asks you to juggle hundreds of variables simultaneously: seasonal trends, supplier lead times, market volatility, customer behavior patterns, and economic shifts. Even the most experienced planners can't process this complexity fast enough to make optimal decisions consistently.

The result? Your inventory becomes a financial burden instead of a strategic asset. Safety stock balloons to cover uncertainty. Emergency orders drain cash flow. Obsolete inventory sits on shelves depreciating in value.

The AI Advantage: How 30% Cost Reduction Actually Happens

AI inventory management doesn't just digitize your existing processes: it fundamentally redesigns how inventory decisions get made. Instead of reactive planning based on historical averages, you get predictive optimization that considers every relevant variable simultaneously.

Precision Demand Forecasting

The foundation of cost reduction starts with knowing what you'll actually need. AI algorithms achieve 95% accuracy in demand forecasting by analyzing patterns human planners simply can't see: micro-seasonal trends, cross-product correlations, external market signals, and real-time behavioral data.

One client saw their forecast error rates drop by 30% within the first quarter of implementation. The ripple effect was immediate: reduced safety stock requirements, fewer emergency orders, and dramatically less obsolete inventory.

Dynamic Inventory Optimization

With accurate demand predictions, AI calculates optimal stock levels for every SKU across all locations. This isn't just about reorder points: it's about understanding the complete network effect of inventory decisions.

The system continuously balances carrying costs against stockout risks, automatically adjusting for changes in supplier performance, lead times, and demand patterns. Companies typically see inventory carrying costs drop by 30-50% as excess stock gets eliminated while service levels actually improve.

Automated Replenishment Intelligence

AI takes over the repetitive, error-prone task of purchase order generation. But it goes beyond simple automation: it optimizes timing, quantities, and supplier selection based on real-time performance data.

This automation eliminates the human errors that cost money: forgotten reorders, duplicate orders, and poor timing that results in expensive rush deliveries or excessive holding costs.

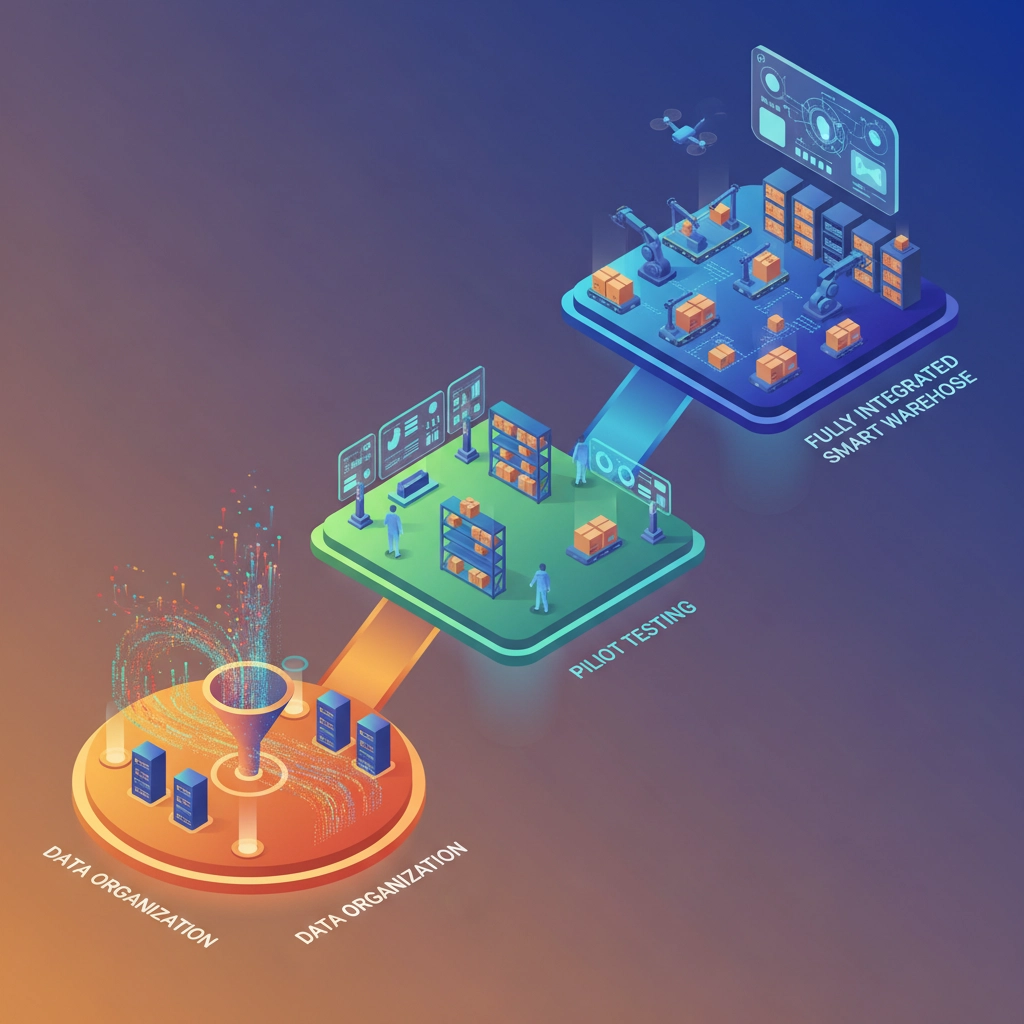

The Implementation Roadmap That Actually Works

We've guided companies through this transformation enough times to know what works: and what doesn't. Here's the practical framework that delivers results:

Phase 1: Data Foundation (Weeks 1-4)

Start by organizing your inventory data into AI-readable formats. This isn't glamorous work, but it's essential. Clean historical demand data, supplier performance records, and inventory movement patterns form the training ground for your AI models.

Common pitfall: Don't try to perfect your data before starting. AI models improve with real-world feedback, so aim for "good enough" data quality to begin implementation.

Phase 2: Pilot Implementation (Weeks 5-12)

Launch with a subset of your SKUs: typically your highest-volume or most problematic products. This controlled approach lets you refine the system while limiting risk.

Focus on demand forecasting accuracy first. Once you're seeing consistent improvements in prediction quality, expand to inventory optimization and automated replenishment.

Phase 3: Full-Scale Deployment (Weeks 13-24)

Roll out across your complete product portfolio, integrating with existing ERP and warehouse management systems. The goal is seamless operation where inventory decisions happen automatically within your defined parameters.

Monitor key metrics throughout: inventory turnover rates, carrying cost percentages, stockout frequencies, and cash flow impact.

Real-World Results: What 30% Cost Reduction Looks Like

Johnson & Johnson's AI system monitors over 27,000 suppliers globally and provides early warning of 85% of supply disruptions with an average 7-day lead time. The financial impact? $300 million in annual inventory holding cost savings.

A manufacturing client we worked with achieved 95% demand satisfaction while increasing profitability by 14%. More importantly, their inventory management shifted from constant crisis mode to strategic control.

The pattern we see consistently: companies transition from spending 80% of their time firefighting inventory problems to spending that time on growth initiatives instead.

Avoiding Common Implementation Pitfalls

Expecting Perfect Data From Day One

AI models improve through use. Start with your existing data quality and let the system learn and refine over time. Perfect data is the enemy of getting started.

Overlooking Change Management

Your team needs to understand how AI changes their roles, not replaces them. Inventory planners become strategic analysts instead of data entry clerks. Warehouse staff focus on exception handling rather than routine reordering.

Setting Unrealistic Timeline Expectations

While some companies see immediate improvements in forecast accuracy, the full 30% cost reduction typically materializes over 6-12 months as the system optimizes inventory levels across your entire network.

The Technology Stack That Delivers

Modern AI inventory management combines several technologies working together:

Machine Learning analyzes patterns in your historical data to predict future demand with increasing accuracy over time.

IoT Sensors provide real-time inventory visibility, feeding actual stock levels back into the optimization algorithms.

Linear Programming calculates optimal procurement quantities and reorder points across your entire supply network.

Natural Language Processing monitors market signals, news, and supplier communications for early indicators of supply chain disruptions.

This isn't about replacing human judgment: it's about giving your team superhuman analytical capabilities.

Building Your AI Inventory Strategy

Every company's path to AI implementation looks different, but the successful ones share common characteristics: they start with clear ROI expectations, invest in data quality, and view AI as an ongoing capability rather than a one-time project.

At Value Chain Management, we've seen how the right approach transforms not just inventory costs but entire business operations. Companies stop making decisions based on gut feelings and start making them based on data-driven insights that consistently outperform human intuition.

The question isn't whether AI will reshape inventory management: that's already happening. The question is whether you'll lead this transformation or watch competitors gain the advantage while you're still fighting spreadsheet battles.

Your inventory should be working for you, not against you. In 2025, AI makes that vision achievable for companies of all sizes, turning inventory from a necessary cost center into a competitive advantage that drives growth and profitability.

Ready to explore how AI can transform your inventory management? Connect with our team at Value Chain Management to discuss your specific challenges and opportunities.

Comments